3D Printing is a process in which three dimensional objects are created under the control of computers.

Today this blog will converse about the 2019 trends of 3D printing.

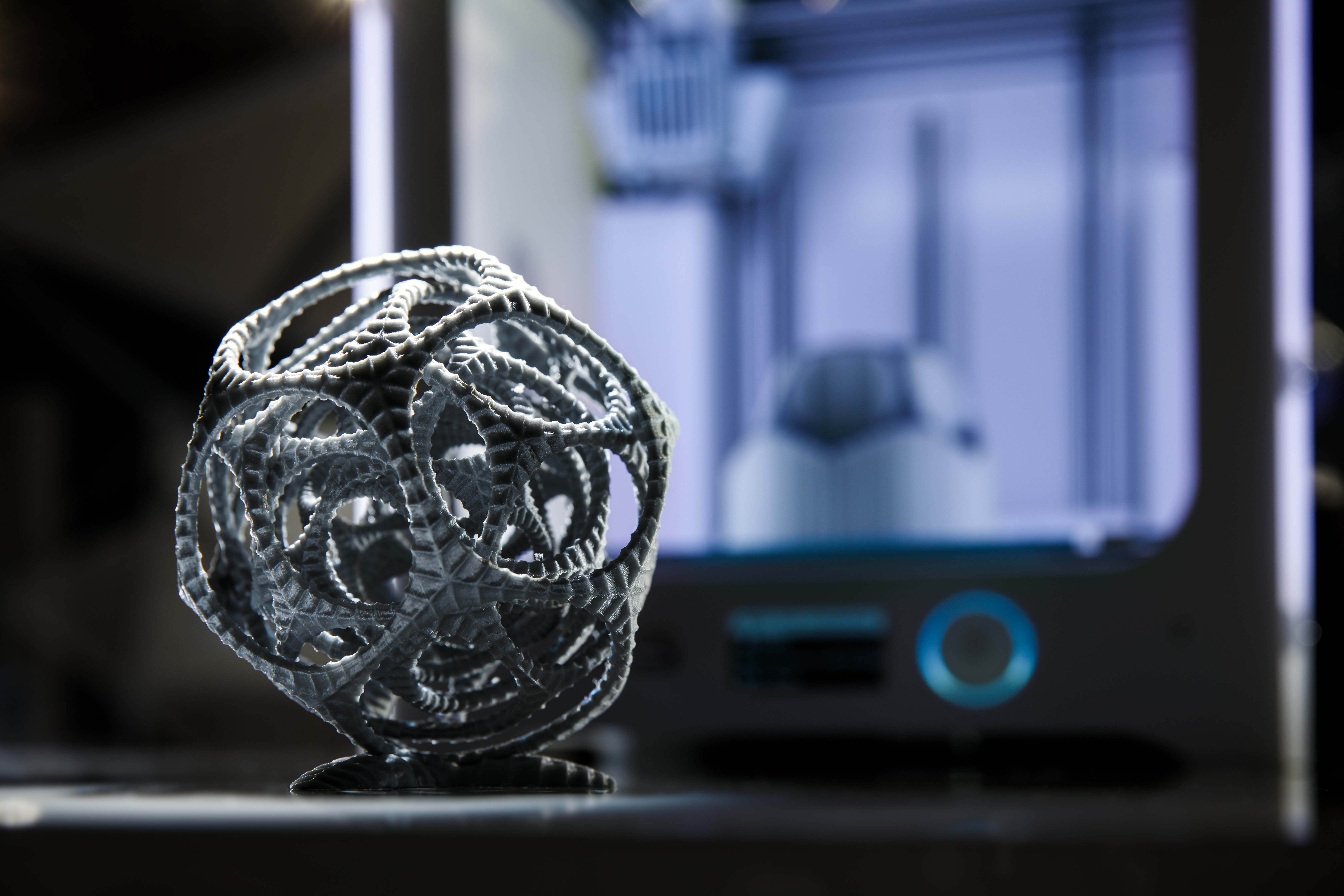

Through 3D printing objects are constructed layer by layer into complex shapes.

This technology is similar to Additive Manufacturing where by successive addition of thin layers objects are created.

3D printing is a three step process.

First the design of the object for printing should be ready.

Second selection of the material should be made; varieties of material are available for 3D printing.

Third is the finishing process where printed 3D product gets the finishing touches.

3D printing helps to produce very complex shapes or geometries.

Polymer 3D Printing Will Expand

From the previous year 2018 3D printing made its position stronger as an industrial manufacturing technology.

With the development in hardware, software and materials 3D printing is becoming important part of the manufacturing process.

Polymers will dominate the overall 3D printing material market.

Polymers are synthetic plastic which are now widely used in 3D printing technology.

Polymer 3D printing has created the space for faster, cheaper and customised tools.

Polymer 3D printing is used to produce medical devices such as prosthetics parts and dental devices.

SLA 3D printing is used today for the manufacturing of more than 90% of hearing aids.

SLA or Stereolithography is a 3D printing process to create models, patterns and production parts in a layer by layer fashion; here light causes chemical monomers to join and to form polymers.

Along with polymer; metal additive manufacturing is also flourishing in the market.

Metal filament is used for the production of lighter materials; 3D metal printing has lot to offer too.

3D Printing Software

A good 3D printing depends on the type of software used.

There are many 3D printing software available in the market such as Maya, 3DS Max, 3D Slash, Wings 3D, Modo, Blender, Rhino 3D etc.

The 3D printing software provides various abilities to the users ranging from modeling to rendering.

3D printing software converts 3D models into instructions that printer can understand; software has greatest impact on print quality.

Maya is useful for 3D printing; it is best for highly detailed models with intricate.

Maya gives smooth surfaces and shapes to the 3D objects.

3DS Max also offers excellent modeling features with its polygon modeling and mesh modeling tools.

Cinema 4D is another modeling tool to create complex 3D designs.

Rhino 3D software is the most versatile 3d modeler.

3D software helps users to craft digital models from which physical objects are created.

Freedom Of Designs

3D printing technology will provide a large amount of design freedom.

This will enable the artist to create very complex geometries.

Complex designs can easily get shapes through this technology.

In 3D printing object’s parts is constructed one layer at a time so design requirements such as draft angles and tool access are not applicable here.

Anything from high-level sporting gear to custom sunglasses can be made by additive manufacturing.

Automated Post-Processing

The post-processing operations are currently relied on manual process which requires skilled operators.

There are multiple 3D printing post-processing techniques to achieve different product results.

Post-processing includes Support Removal, Sanding, Vapour Smoothing, Primer and Painting and Polishing.

Post-processing increases the aesthetic, strength and feel of the objects.

Support removal can be done by hands or cutters but they leave some marks which are further smoothed by sanding.

Sanding requires lot of time and effort; this process is carried out by using sandpaper of varying grits.

Vapour Smoothing is performed after sanding where Acetone is used for the technique.

In Vapour Smoothing; vapour of acetone reacts with the outer layer of the 3D object to give glossy look to the object.

Primer is applied to the 3D object before painting to protect it from rust.

After priming, model gets dry and then painting can be carried out.

Painting can be carried out by using brush or sprays.

Polishing comes at the end; it enhances the final product of the 3D print.

Post-processing techniques help in achieving desired look and feel of the 3D objects.

Technology Interconnectivity

Manufacturing sectors like automotive, aerospace and consumer goods industry is looking forward to 3D printing for its design benefits.

With market share of $12 trillion; 3D printing industry offers technology neutral solutions.

3D printers are used in medical industry to design body parts; starting form metal joints to prosthetic masks; medical industry has accepted 3D printing for advancement.

The year 2019 will be more innovative for medical industry.

In aviation lightweight parts will replace the heavy metallic parts.

For example Andreas Bastian from Autodesk has combined 3D metal printing with investment casting to produce magnesium-based airplane seats which are about 50 percent lighter than traditional seats.

Companies like Adidas and Nike have already used 3D printers to produce objects at large scale.

Industrial manufacturers who are thinking seriously to adopt 3D printing as a harmonious manufacturing technology for final productsshould come out of proprietary solutions that limit their flexibility and choice.

3D printing will create new business opportunities among the manufacturers.

In 3D printing; technology and manufacturing is working together to become more flexible and efficient.

Manufacturing process will witness an automated form of marketing in the year 2019.

3D printing is helping the industry to think faster, create better and widespread in the horizon of manufacturing.

Unlike tradition manufacturing where heavy machines and manpower are used; labour costs for 3D printing is almost zero.

3D printing technology produces very little waste as it only uses the material needed to build a part.

3D printing has enhanced its field in sectors such as automotive, healthcare, military, consumer products, aerospace, education, industrial products and research.

It helps in reducing production cost by avoiding expensive mistakes.

3D printing has crossed the challenges over the last few years and has established itself as a solution for industrial applications.

2019 will be a great year for 3D printing as it will pave the way towards growth and maturity.

Know more about 3D Technology by joining our reputed MAAC Kolkata Centers.